The highly traveled bridge to West Seattle will soon have some new carbon fiber bones.

When Seattle engineers spotted cracks rapidly widening in 2020, the city made the tough call to shut down the bridge, one of the busiest in Seattle, disrupting a major route in the interest of safety. The repairs, slated for completion this summer, will restore the thoroughfare.

To the east, near downtown Spokane, a major bridge on I-90 in poor condition also desperately needs structural fixes, even as an estimated 40,000 vehicles traverse it every day.

Just a few miles from there, Rosamond Avenue Bridge crosses over I-90, but the bridge was closed last April because of cracks and heaving on the deck—and no funding to fix it.

Millions of vehicles rumble across more than 614,000 bridges every day in the United States. Many of them are in poor condition and getting worse, along with countless miles of roads requiring maintenance in the Pacific Northwest and across the country.

(Courtesy Seattle Department of Transportation)

Yet, it’s not just about steel, concrete, and asphalt.

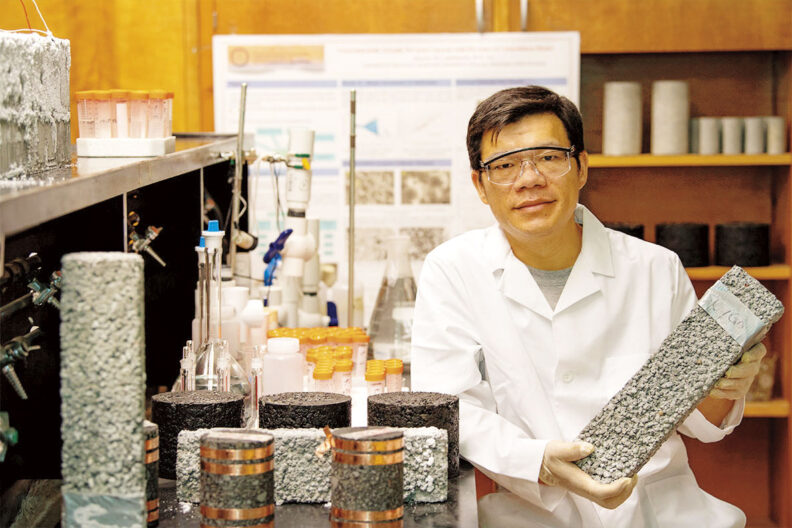

“The risks to reliability and safety of the overall system affect everybody’s daily life,” says Xianming Shi in the Voiland College of Engineering and Architecture at Washington State University. “We’re at a stage where we can send people to Mars, we can think about flying cars or autonomous vehicles, but our bridges are in such a dire condition and roads are full of potholes.”

Shi studies ways to improve bridges and roads as a professor in the Department of Civil and Environmental Engineering. He also leads the National Center for Transportation Infrastructure Durability & Life-Extension (TriDurLE), a consortium of 11 universities funded as the only national center with the focus on infrastructure durability, sponsored by the US Department of Transportation. The researchers from WSU and around the United States aim to make bridges and roads more durable and significantly increase their lifespans.

It’s a driving need. The bridge collapse near Pittsburgh, Pennsylvania, that injured ten people earlier this year alerted people again to the desperate state of the largest transportation infrastructure system in the world.

The American Society of Civil Engineers gave US roads a “D” and bridges a “C” grade in 2021, with nearly $790 billion needed in immediate investment. Those structures face wear and tear hastened by climate extremes, natural disasters like earthquakes, and increases in traffic as populations grow.

Through advanced and cost-effective technologies such as nano-sealers for concrete, carbon fiber reinforcement of bridge columns, and AI-driven monitoring, Shi and the national center’s members work with state and federal transportation departments, as well as business partners, to better secure bridges and roads for travelers.

A bridge problem

Mark Gaines, state bridge engineer with the Washington State Department of Transportation (WSDOT), has worked for almost 22 years on the state’s transportation infrastructure. He doesn’t sugarcoat the problems.

Gaines says Washington state is only about 40 to 50 percent funded on preservation needs for bridges. “That means our bridges get about 50 cents on the dollar for what they actually need to be maintained in a state of good repair,” he says. “The consequence is that, over time, we’re going to see the condition deteriorate. Right now, we’re at about 6 or 7 percent poor bridges.”

He does note that poor conditions are different than safety issues. “Safety is managed by our inspection teams and if we see a bridge isn’t safe out there, we take quick action to restrict or to shut it down.” The city of Seattle made a similar call with the West Seattle span, which is not managed by WSDOT, Gaines notes.

Still, he says, if poor conditions aren’t eventually addressed, there will be more closures, more load postings, and more restrictions on bridges as they deteriorate. In 2021, WSDOT managed 3,143 bridges and 131 of them were load-restricted or load-posted.

The deferred work on many bridges adds to the state’s fix-it list, too. WSDOT-owned bridges in poor condition increased from 164 bridges in June 2020 to 179 in June 2021. The number of bridges 80 years old or older—those with the most significant needs—climbed from 292 in June 2020 to 302 in June 2021.

It’s not a problem unique to Washington state. About 8 percent of US bridges are considered poor. One out of every five miles of highway pavement is in poor condition.

The TriDurLE consortium works with WSDOT, Idaho Department of Transportation (ITD), and other state transportation departments to not only mitigate existing issues, but also find new ways to extend the lifespan of bridges and roads. The universities in TriDurLE, led by WSU, cover the United States and are charged with innovative research that’s high risk and high return at times, Shi says.

“We have around 50 ongoing seed-grant projects looking at, for instance, self-healing concrete, greener ultra-high performance concrete, and drone-enabled bridge inspection,” he says. “We can quickly diagnose the post-earthquake condition and residual load-bearing capacity of bridge piers, coupling artificial intelligence algorithms with images captured by drones.”

A few other areas of inquiry include using resources such as recycled plastic and fly ash in asphalt and concrete, repurposing agricultural waste for deicing, and designing bridges to be more resilient in earthquakes. The national reach of the center helps the scientists understand regional differences, as well.

“We try to identify collaborators who represent different infrastructure challenges in different climatic zones, because Minnesota or Washington would be dealing with different challenges than Florida,” Shi says.

TriDurLE also facilitates technology transfer, education, and workforce development. “It’s not just everything happening in the lab. We’re looking at how to engage students, especially those in diverse and underrepresented groups, to join research and get them interested in a transportation career,” he says.

Shi’s own academic background gives him an interesting perspective on transportation infrastructure. Although he’s a fellow of the American Society of Civil Engineering, Shi studied industrial management and chemistry, and in particular polymer chemistry and corrosion protection, which are highly relevant to bridge engineering.

Shi’s research team, for example, has applied understanding of chemistry to develop nano-engineered penetrating sealers to keep moisture out of concrete and fill cracks in bridges and other structures.

Roadway deicers (including rock salt) and moisture can accelerate the failure of concrete structures that endure freeze and thaw cycles. With some cracks smaller than the human eye can see, such culprits make their way inside the concrete and could corrode the steel rebar.

“Once the concrete’s cracked, all the water, salt, CO2, everything gets in much faster. So, from that point it’s usually three to ten years before a bridge is failing,” Shi says. “You don’t want to get to that stage; you want to intervene earlier. The typical design life of a bridge is 50 to 75 years. But with this kind of intervention early on, you can make that bridge last 100 years or 150 years.”

While WSU researchers are also looking at alternatives for the more than 20 million metric tons of salt dumped on US roads to keep them clear of ice and snow, Shi’s work could make a big impact on bridges that are already compromised.

The novel sealer developed by Shi and WSU graduate student Zhipeng Li showed a 75 percent improvement in repelling water and a 44 percent improvement in reducing salt damage in laboratory studies compared to a commercial sealer.

They added two nanomaterials, graphene oxide and montmorillonite nanoclay, to a commercial penetrating sealer, which further repelled water and made concrete denser. That makes it more difficult for moisture to penetrate and forms a barrier against physical and chemical damage from deicing salt.

The sealer developed by Shi and Li is also water-based and more environmentally friendly. They have applied for a provisional patent and, after a pilot study in Pullman over the next two years, the researchers would like to see the technology commercialized.

Nanocomposite sealers over rebar steel, another area of research, could also notably extend the service life of a reinforced concrete structure such as a bridge.

Shi and other TriDurLE researchers are investigating more than just sealing cracks. Concrete itself, the most used construction material in the world, can be altered with recent advances in nanotechnology and bio-concrete, giving the material self-sensing and self-healing properties. Intelligent concrete can optimize durability and adapt to a changing environment.

The ability to adapt comes at a crucial time. Last summer, Northwesterners, and anyone watching the news, saw what unpredictable climate shifts can do to roads, concrete, and asphalt. The buckling and cracking under record-high temperatures were a visible reminder of how roads and bridges can get damaged quickly.

More snow, rain, and freezing can also be a symptom of a chaotic climate, which exacerbates the need to fix bridges. But another potential hazard lingers in the minds of transportation officials and researchers: the big one.

A seismic shift

At almost 11 in the morning on February 28, 2001, Western Washington started shaking. A 6.8 magnitude earthquake with its epicenter about 10 miles northeast of Olympia damaged buildings, roads, and bridges across the region. The Nisqually Quake, the first major seismic event in the area since 1965, accelerated WSDOT plans to retrofit older bridges to prevent catastrophic collapses or further damage.

The most significant damage was to the Alaskan Way Viaduct, which experienced significant cracking and settlement likely due to liquifiable soils in the Seattle area. Fortunately, many other Washington bridges held up well.

WSDOT had already started seismic retrofitting on bridges built before 1983. Bridges constructed from 1983 on were designed for seismic events and are expected to perform reasonably well during an earthquake. In recent years, Gaines says, the department concentrated on “lifeline” bridges, ones designed so that emergency vehicles and suppliers can use them even in the worst disasters.

After 2001, WSDOT completed retrofits on 323 bridges and partial retrofits on 114 more. Several high-profile bridge projects in the central Puget Sound area increased seismic resilience, especially the 2016 opening of the new SR 520 floating bridge and the 2019 Alaskan Way Tunnel replacement of the original damaged viaduct.

A number of bridges, particularly 103 of them along lifeline routes, still await work. It’s a pressing concern for the department, especially with the possibility of a massive earthquake along the Cascadia Subduction Zone.

Gaines says that older bridges “are not designed for lateral movement of the ground shaking that you’re going to see during a big event. So, one of the susceptibilities for most of the bridges from before the 1970s are in the columns.”

The traditional method of reinforcing bridge columns against seismic damage is surrounding them with a steel jacket. It leaves a bit of a gap between the concrete column and the jacket, which is filled with cement grout to ensure full contact between the column and the jacket.

The department is looking at moving more toward carbon fiber and composite type materials, which are generally as effective as steel jackets in confining the columns but are often easier to install.

WSU civil engineering researchers Chris Motter and Adam Phillips, both part of TriDurLE, have been analyzing bridge column jackets made of steel and carbon fiber, as well as resilience in a large and long seismic event.

“Seismologists are starting to better understand what we can expect from the fault,” Motter says. “They’re talking about a large magnitude, long duration earthquake. So, it could be strong shaking for multiple minutes. We’ve tried to really get that feature of the earthquake into our study.”

The pair work with University of Washington and US Geological Survey experts, who simulate Western Washington ground motions from a rupture of the Cascadia Subduction Zone. Motter and Phillips use that information to run bridge failure simulations, also using materials donated by Simpson Strong-Tie.

Phillips says the structural dynamics of a bridge change the reaction, too. “Generally, a longer bridge is going to have a longer period of vibration. It’ll oscillate back and forth slower than a shorter bridge.”

Many bridge columns, they say, tend to be pretty brittle if they don’t have much rebar in them. A jacket, steel or otherwise, maintains the integrity of the column. In a long duration earthquake, though, the vertical rebar actually fractures from the fatigue.

According to Motter and Phillips, the advantage of a carbon fiber jacket is mostly twofold. First, there’s less corrosion than steel, which is even more important in places close to salt water. Second, as Gaines noted, installation costs less and is more convenient.

Steel jackets require heavy equipment and possibly shutting down lanes of traffic. With carbon fiber, Motter says, “they can show up in a pickup truck, pull off the road and just do it. And the price of carbon fiber material has come down over the last 10 to 20 years.”

Phillips says they’re encouraged by the results of their study so far which show that bridges with retrofitted columns can withstand a powerful, longer earthquake.

Gaines says the most important thing is that, by designing new bridges and retrofitting older ones for larger earthquakes, WSDOT and other transportation departments in seismically active states can keep the bridges standing and save lives.

A road to somewhere

While earthquakes might not be as much of a concern in the Inland Northwest, weather and other conditions wear down roads as well as bridges. Drive east from Spokane on I-90 and you’ll end up on Idaho roads and bridges that face, like Washington and all states, a backlog of needs to make sure people can travel safely.

One way to prioritize that list of projects is to use machine learning to determine the best use of funds.

In coordination with TriDurLE and Shi, the ITD is developing better prediction models powered by artificial intelligence to more reliably determine when to intervene and prevent deterioration.

Riley Bender (’16 Civ. Eng.) is the district materials engineer for the ITD based in Lewiston. He coordinates with WSU researchers on the project, which wraps up this summer.

(Courtesy ITD)

“We use the data that we collect on roads every year, on things like cracking, rutting, and smoothness of the road, to help us plan future paving projects. That’s something that every transportation department does as part of a requirement for federal funding,” Bender says.

The new model is a more advanced prediction of how pavement deteriorates. Asphalt will fail, he notes, and “if we can better predict the failure of pavements over time, we can apply the right fixes at the right times, which in turn helps us preserve the whole statewide highway system.”

Weather and traffic factor into the algorithms, too, allowing the ITD to take a targeted approach to their road fixes. In 2020, 87 percent of Idaho’s roads were in good or fair condition, and Bender would like to see that get even better.

“I drive on the highway, just like everybody else,” Bender says. “I want to make sure that it’s to the requirement that we need.”

A better path to travel

Shi compares the growing problems with bridges and roads to deferred car maintenance that ends up costing more. “If you intervene at the right time early on, then you spend $10. But if you don’t, five to ten years later you end up spending $60 to $100 to fix the problem.”

With that domino effect, he says, we cannot keep up with maintenance in an annual budget and thus need a boost in funding. The federal infrastructure funding could help in that regard, says Shi, but more is needed—possibly from states or the private sector.

“One thing I took away from my education as an industrial engineer is that no matter how good the system is, there’s always room for improvement,” Shi says. “We’ve talked about infrastructure for decades. We can’t keep kicking the can down the road.”

Shi says one big task is getting ideas from the lab to the streets.

Unlike Europe and Asian countries such as South Korea, Shi says, industry in the United States often does their own R&D, while universities do theirs separately. He points to the example of self-healing concrete, which is already being commercialized in Europe, South Korea, and other places.

Partnership with companies such as Kiewit and Simpson Strong-Tie could really bolster the work, Shi notes. “They’re more experienced in bringing technology to practice. We need better coordination and collaboration between industry and academia.”

Interstate 90 bridge over Latah Creek in 2009 (Photo Thaddeus Roan)

Interstate 90 bridge over Latah Creek in 2009 (Photo Thaddeus Roan)

Web extra

Map: The state of Washington state bridges (ArcGIS offsite link)

(For further information regarding the specific bridge elements in poor condition corresponding the highlighted locations in the above map, cross-reference this PDF.)

On the web

National Center for Transportation Infrastructure Durability & Life-Extension (TriDurLE)

Infrastructure Report Card (American Society of Civil Engineers)

Researchers uncover hidden deicer risks affecting bridge health (WSU News, 2019)

Washington State Department of Transportation – Preserving roads and bridges

3 Ways to Give a Facelift to America’s Crumbling Roads (Daily Beast, 2021)